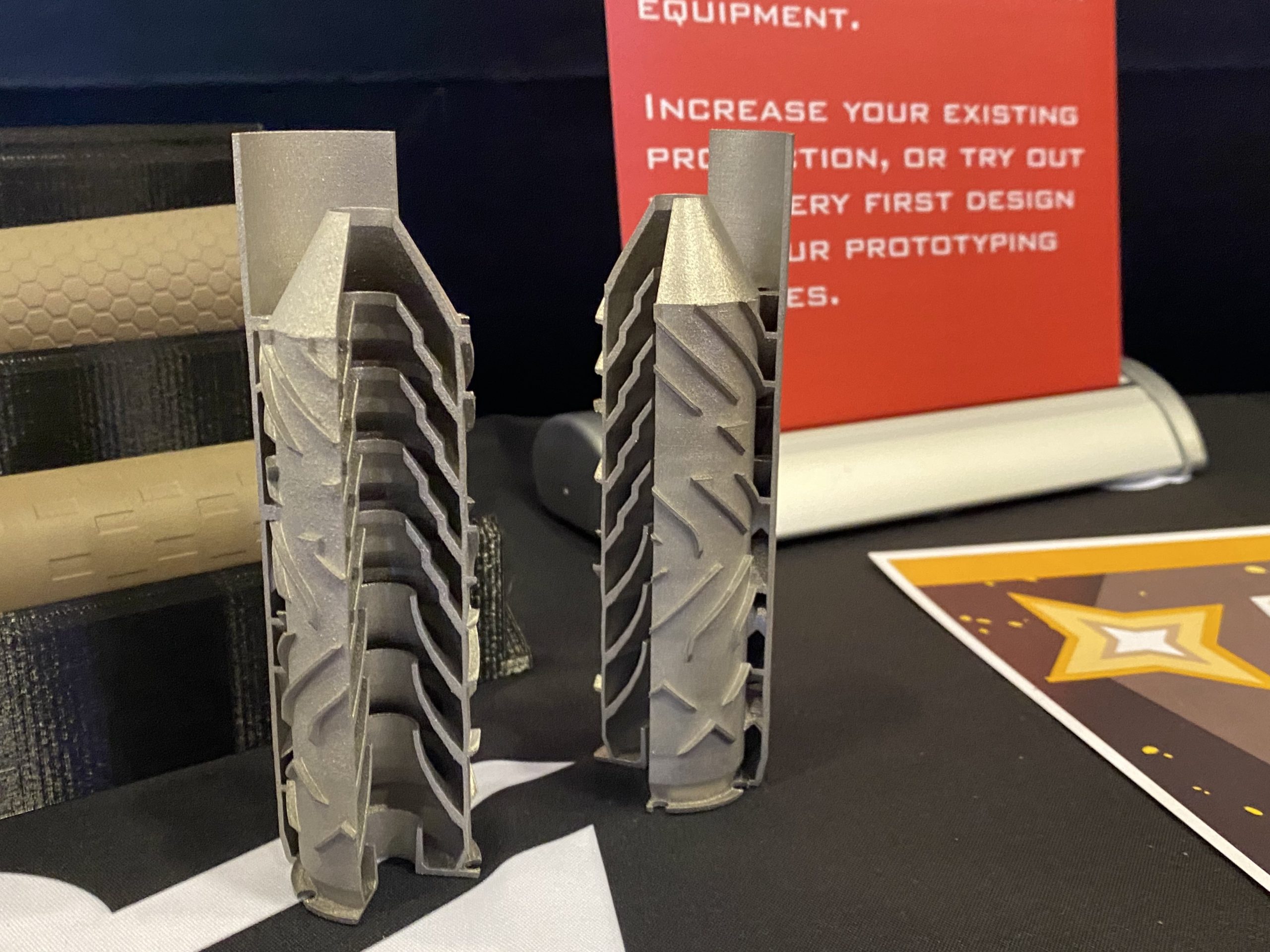

Having recently completed a course in additive manufacturing (3D Printing) its interesting for me to see how this technology is being used in the firearms design space. Much like how we are starting to see metal additive a lot more in the aerospace world the unique ability for additive to produce things in one piece that aren’t able to be made with conventional machining lends itself well for suppressor manufacturing. The first printed suppressors I saw were from Delta P Design and it was basically a coke can in size. Since then things have really advanced in the metal additive market. Replicator USA has entered the frey with 3 models to cover the basis of what most people are looking for. They do make some bold claims so it will be interesting to see what Pew Science has to say if they get a hold of some copies.

The ad copy for their suppressors makes a bold claim of zero back pressure but they are made from inconel which will be durable. If they are able to reduce the back pressure to near zero this is a good thing as it means the suppressor is plug and play with no gas system tuning, fancy bolts or adjusting springs and buffers. The suppressors are manufactured and quality-tested in-house. Through testing of 3D printed metal is always a good thing to ensure the product is optimally bonded together since it is made of tiny layers of metal powder. While I take issue with the superfluous ad copy for a newer company claiming what they make is the most advanced 30 cal, 9mm and 5.56 suppressors I do like some of the options that comes with additive manufacturing.

The ad copy for their suppressors makes a bold claim of zero back pressure but they are made from inconel which will be durable. If they are able to reduce the back pressure to near zero this is a good thing as it means the suppressor is plug and play with no gas system tuning, fancy bolts or adjusting springs and buffers. The suppressors are manufactured and quality-tested in-house. Through testing of 3D printed metal is always a good thing to ensure the product is optimally bonded together since it is made of tiny layers of metal powder. While I take issue with the superfluous ad copy for a newer company claiming what they make is the most advanced 30 cal, 9mm and 5.56 suppressors I do like some of the options that comes with additive manufacturing.

With additive manufacturing, you are able to offer a much larger degree of customization than what you could with a normal product. You don’t need to change out the tooling to get various surface textures. Replicator offers their suppressors with smooth, hexagon, triangles, rectangles, helix and smooth with roll tabs. Along with this, you can get them in black or FDE and they are supposedly full auto rated. The prices on these are looking to be around $1000 USD.

With additive manufacturing, you are able to offer a much larger degree of customization than what you could with a normal product. You don’t need to change out the tooling to get various surface textures. Replicator offers their suppressors with smooth, hexagon, triangles, rectangles, helix and smooth with roll tabs. Along with this, you can get them in black or FDE and they are supposedly full auto rated. The prices on these are looking to be around $1000 USD.

I look forward to seeing how these make out and what the future of additive manufacturing looks like for the firearms space.